E-Lab Filler: the compact and intelligent machine for customized diagnostic device filling

In today's medical and diagnostic industry landscape, there is a growing demand for flexible, regulation-compliant, and cost-effective solutions for small or variable productions. This is especially true for manufacturers of in vitro diagnostic (IVD) devices, reagents, micro-vials, analysis cartridges, rapid test kits, and customized devices intended for laboratories or analytical platforms.

E-Lab Filler Mini: Customizing a Standard Solution for a Diagnostic Industry Client

The E-Lab Filler Mini - See Video Here - has been designed as a compact, flexible, and highly adaptable filling machine, capable of evolving from a standard semi-automatic unit into a fully customized automated solution.

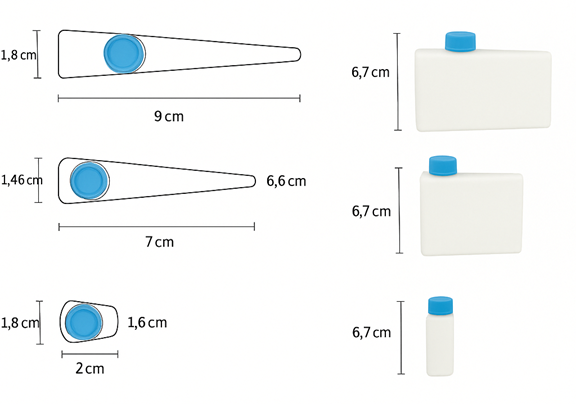

This case study presents the development path for a specific client in the diagnostic sector. The client's requirement is unique: they need to manage small production quantities with the same machine, while accommodating different container volumes with high filling accuracy. The system must handle three or four very different container types, all sharing a common cap design. The shapes of the containers are very specific. They are similar to the shapes required by an analyzer like COMpacta 270 - Comedical

Handling Multiple Container Types

The client provided three types of containers with different shapes and capacities, as illustrated in the attached technical drawings and product images. Although the dimensions and profiles differ significantly, the presence of a common cap across all container types allows the E-Lab Filler Mini to streamline capping and decapping processes. This versatility ensures that the same automation platform can manage a wide range of formats without excessive changeover times or mechanical adjustments.

Initial Phase: Manual Loading with Automated Processing

Given the client's current low production volumes, the project will initially start with manual container loading into the machine, with the cap already mounted. The E-Lab Filler Mini will automatically uncap, fill, and recap each container using its integrated automation. The system will identify the applied torque during capping, verify the container's condition through an AI-powered vision system, and allow batch-by-batch weight verification to be recorded. All production data will be documented in a Batch Record created within Engmotion’s secure environment for the client.

Advanced Software and Integration

The customized E-Lab Filler Mini will be connected to the client’s central ERP system. It will include hierarchical access control, calibration management, product recipe handling, and comprehensive production Batch Record management with a full audit trail. The machine’s software will be developed to ensure compliance with regulated industry requirements, guaranteeing traceability and operational security.

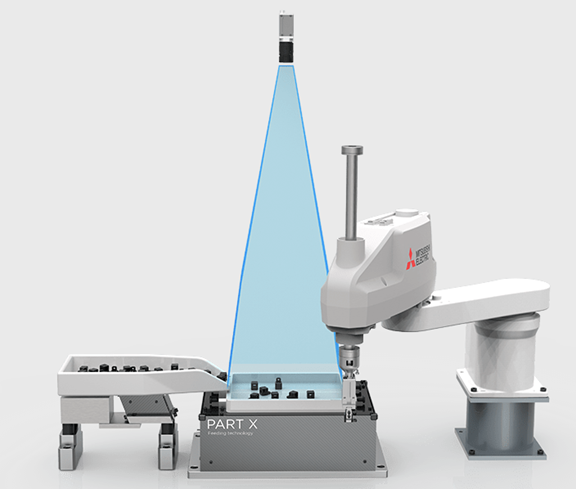

Future Evolution: Fully Autonomous Operation

The client has expressed interest in evolving the system towards a fully autonomous solution. The future concept includes a SCARA robotic arm capable of identifying container types via an AI-based recognition system, picking them from a 3D vibrating plate (provided by www.industry-devices.com) without human intervention. The same automation would also manage output handling, labeling, and verification processes. The E-Lab Filler Mini platform is being engineered from the outset to be fully compatible with this future expansion.

From Standard to Custom: Meeting Complex Production Needs

This project demonstrates how a standard Engmotion E-Lab Filler Mini can be transformed into a highly specialized solution tailored to a client's unique operational requirements. By integrating mechanical adaptability, AI-powered vision inspection, advanced software integration, and the potential for future robotic automation, the machine is designed to support controlled, efficient, and precise production flows. This represents not just a filling machine, but a scalable platform for continuous improvement and innovation.