E-Lab Filler MINI: The Big Impact of a Compact Solution

The E-Lab Filler MINI was born from the voices of customers who sought an affordable, compact, and versatile filling machine—something far beyond a simple filling pump.

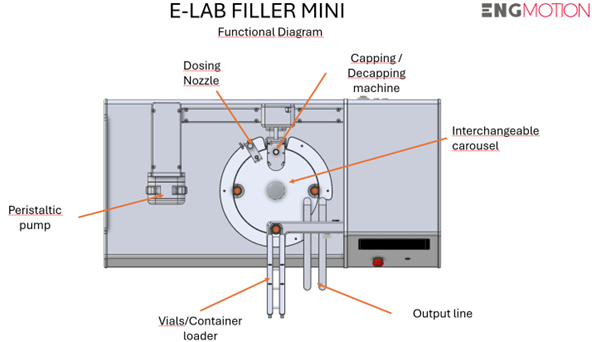

Clients wanted a machine that could handle small batches, process plastic vials at speeds of 200 to 400 units per hour, and go beyond standard filling to include automated capping.

Most importantly, they wanted an efficient, European-built solution with reliable support—without the high price tag typically associated with industrial equipment of this quality.

For a DEMO at Pharmintech click here

For a DEMO at Pharmintech click here

The Challenge: Creating a High-Performance Machine in a Small Package

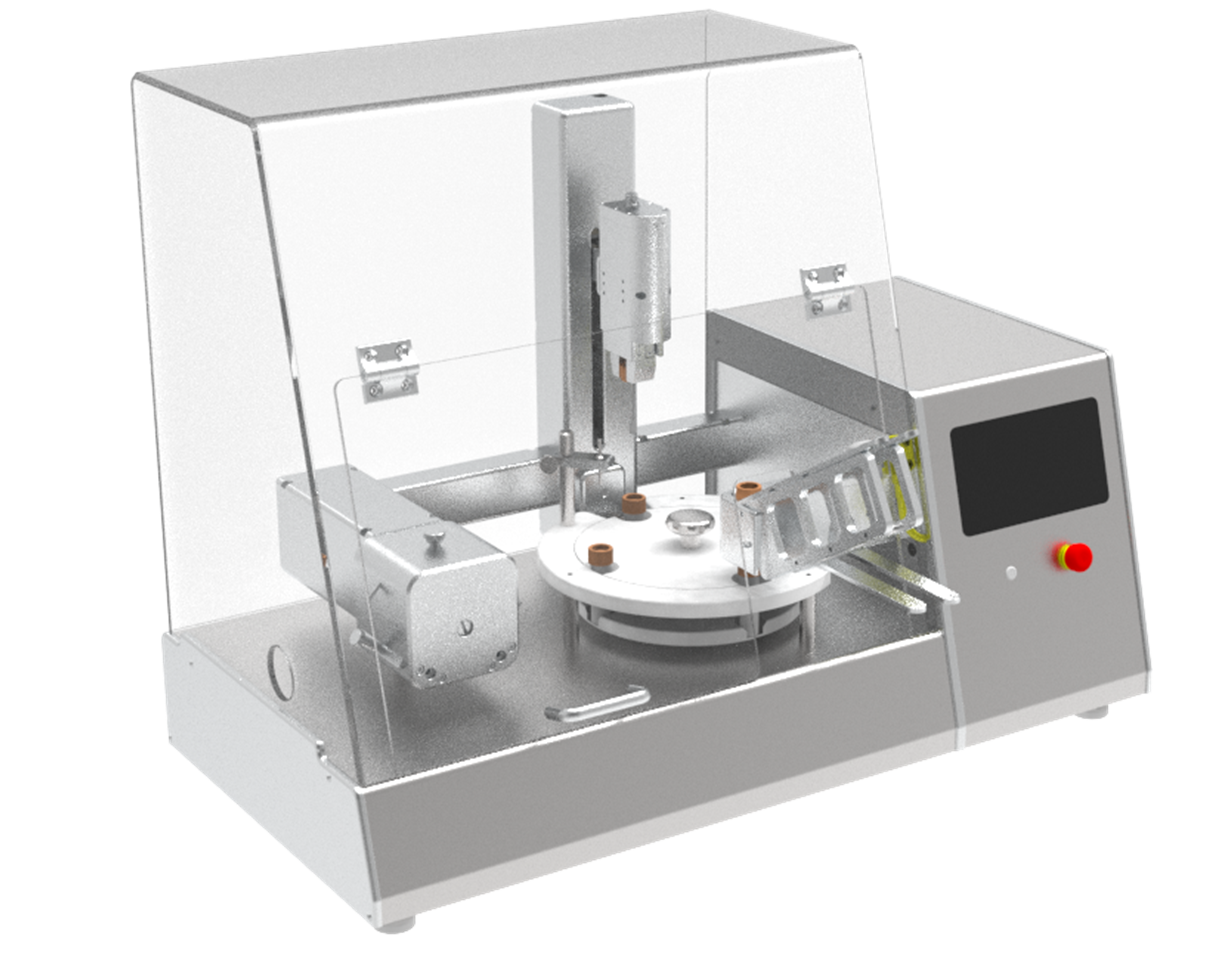

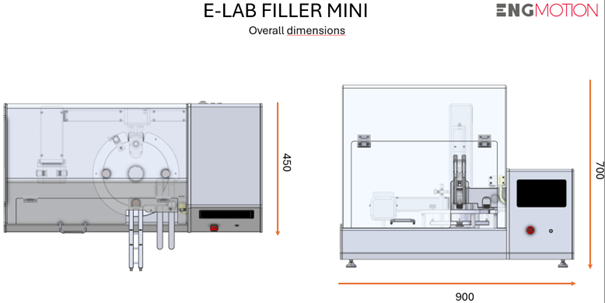

The path forward was clear but challenging: create a machine that not only meets high standards for functionality and automation but also fits a remarkably small footprint. In response, our team rolled up their sleeves to design a solution with everything packed into a compact, bench-top format, engineered to the highest standards. Our goal? To offer a competitively priced machine that rivals options from the Far East—without compromising on quality or precision. Slovenian Made.

Inside the Evolution of E-Lab Filler Mini: A Journey of Design, Customization, and Innovation

At Engmotion, our journey with the E-Lab Filler Mini began with a simple yet ambitious goal: to create a compact, versatile filling solution tailored to the needs of professionals managing small batches and intricate filling tasks. Every step in its development has been fueled by close collaboration with users and a commitment to innovation. Today, the E-Lab Filler Mini stands as a symbol of customization, efficiency, and adaptability in the filling machine industry, especially for those working in limited spaces with demanding requirements.

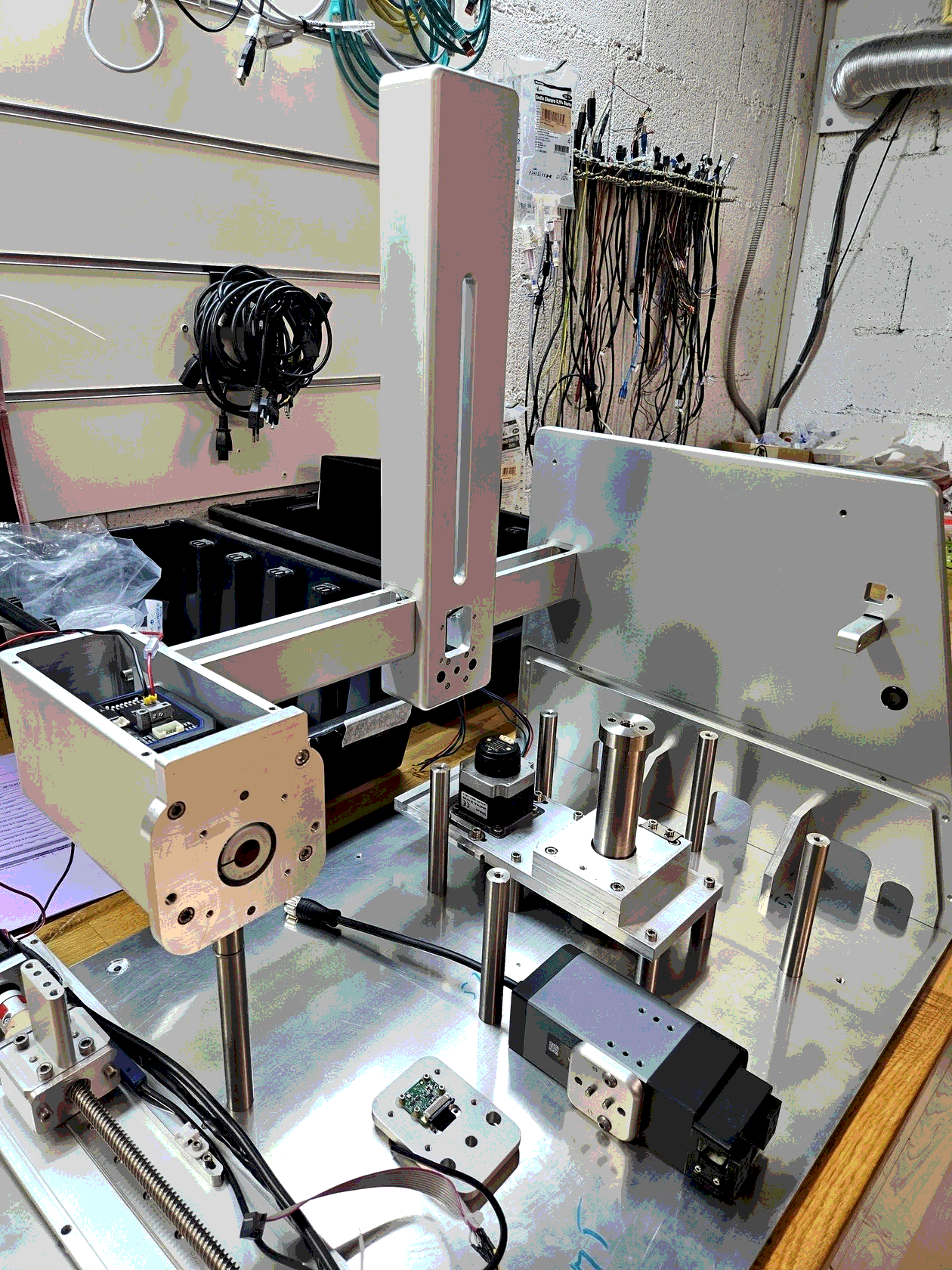

From Concept to Prototype: Designing the E-Lab Filler Mini

The process began with deep insights from users who faced challenges with manual or non-specialized equipment. Our team understood that the key to solving these issues lay in building a compact machine that would simplify batch handling while maintaining high standards of precision. In our design process, we focused on creating a small footprint, easy mobility, and modular components, ensuring flexibility without compromising quality.

From the initial design sketches, our CNC department got to work crafting essential components with precision and attention to detail. The result is a machine as beautiful in its engineering as it is powerful in its capabilities. Every aspect of the E-Lab Filler MINI has been developed in-house: from design to CNC-machined components, through to electromechanical assembly, testing, and validation. It’s a product of our expertise and craftsmanship, designed to make a lasting impression on our clients.

Compact, Flexible, and Robust

The E-Lab Filler MINI is a true industrial machine on a small scale: flexible, reliable, and built to handle demanding tasks. This compact powerhouse can easily integrate automation, including an optional automatic feeder, making it highly adaptable for various applications. And while it’s designed with Pharma expertise, it’s optimized for clean, rather than sterile, product handling—ideal for testing and other non-sterile applications.

Customization at Its Core

One of the standout features of the E-Lab Filler Mini is its adaptability. From the start, we envisioned a machine that could evolve with our users’ needs. Through close collaboration with our clients, we enabled a high degree of customization, ensuring that the machine integrates seamlessly into any workflow. This customization spans from software to hardware elements, allowing operators to handle various container types and easily transition between products.

Continuous Evolution and Internal Development

Unlike many machines on the market, the E-Lab Filler Mini is the result of a fully internalized development process. This approach has given us the freedom to innovate quickly, continuously improving and refining features based on real-time feedback. Our engineering and R&D teams work in sync to address emerging needs, incorporating cutting-edge technologies and user-friendly upgrades. This internal evolution allows us to anticipate market demands and deliver a machine that remains relevant and competitive over time.

The Future of E-Lab Filler Mini

Looking ahead, we are committed to integrating AI and smart technologies, making the E-Lab Filler Mini not only a machine but a smart assistant in production. As we advance, the machine will become even more autonomous, reducing repetitive tasks and empowering operators to focus on higher-value work.

The E-Lab Filler Mini is more than a product; it's a testament to Engmotion’s dedication to creating solutions that simplify complexity. We invite you to experience this compact powerhouse and see how it can transform your workflow.

Delivering on Our Promise

The E-Lab Filler MINI offers exceptional performance, quality, and price—an ideal choice for professionals who want to demonstrate their commitment to excellence. With the E-Lab Filler MINI, you get a powerful machine that’s as easy on the budget as it is on workspace. We’re proud to offer a solution that brings European engineering quality and support to our customers at an incredible value.