Why Partnering with a Trusted CNC Manufacturer Makes All the Difference for Prototypes and Small-Batch Production

In the world of prototyping and limited-run CNC machining, every detail counts. When creating parts that may only need to be produced in small quantities or as prototypes, it’s crucial to work with a manufacturer that provides not only precise machining but also expert support through every stage—from engineering and design to material selection and finishing. But why is this level of trust and expertise so important?

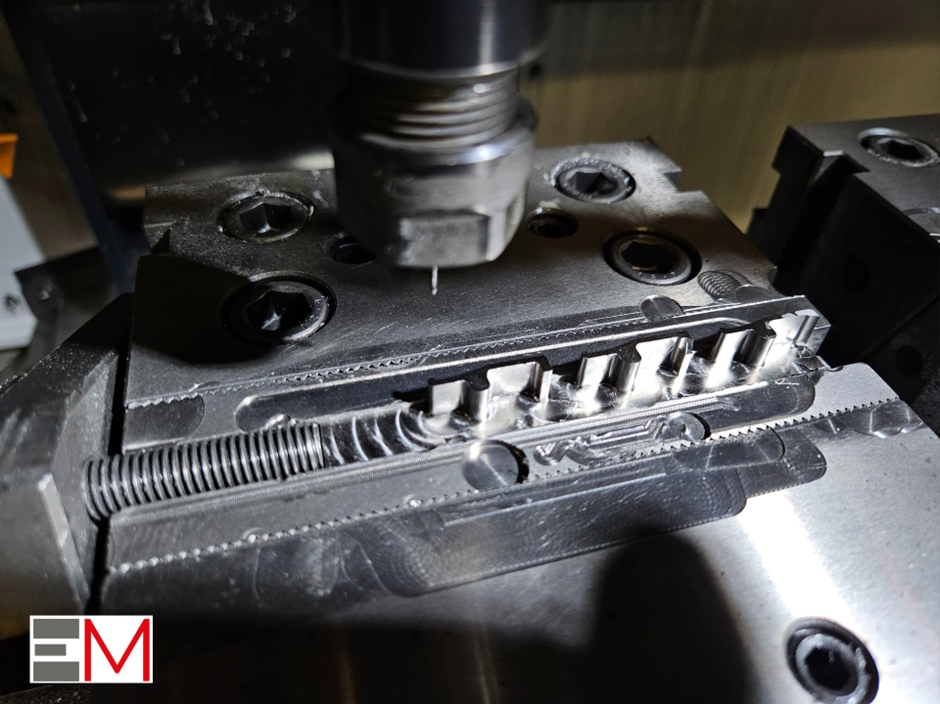

Precision and Quality, From the Start

Prototype and small-batch components must often meet final-use specifications from the first iteration. There’s little room for error, and the process requires a deep understanding of tolerances, material properties, and finishing techniques. Choosing a reliable CNC partner ensures that each part is produced with meticulous accuracy, meeting exacting standards. At Engmotion, we understand this demand for precision, and our specialized engineering team provides the support and expertise that many clients need to transform their ideas into reality.

Engineering Support That Goes Beyond Standard Production

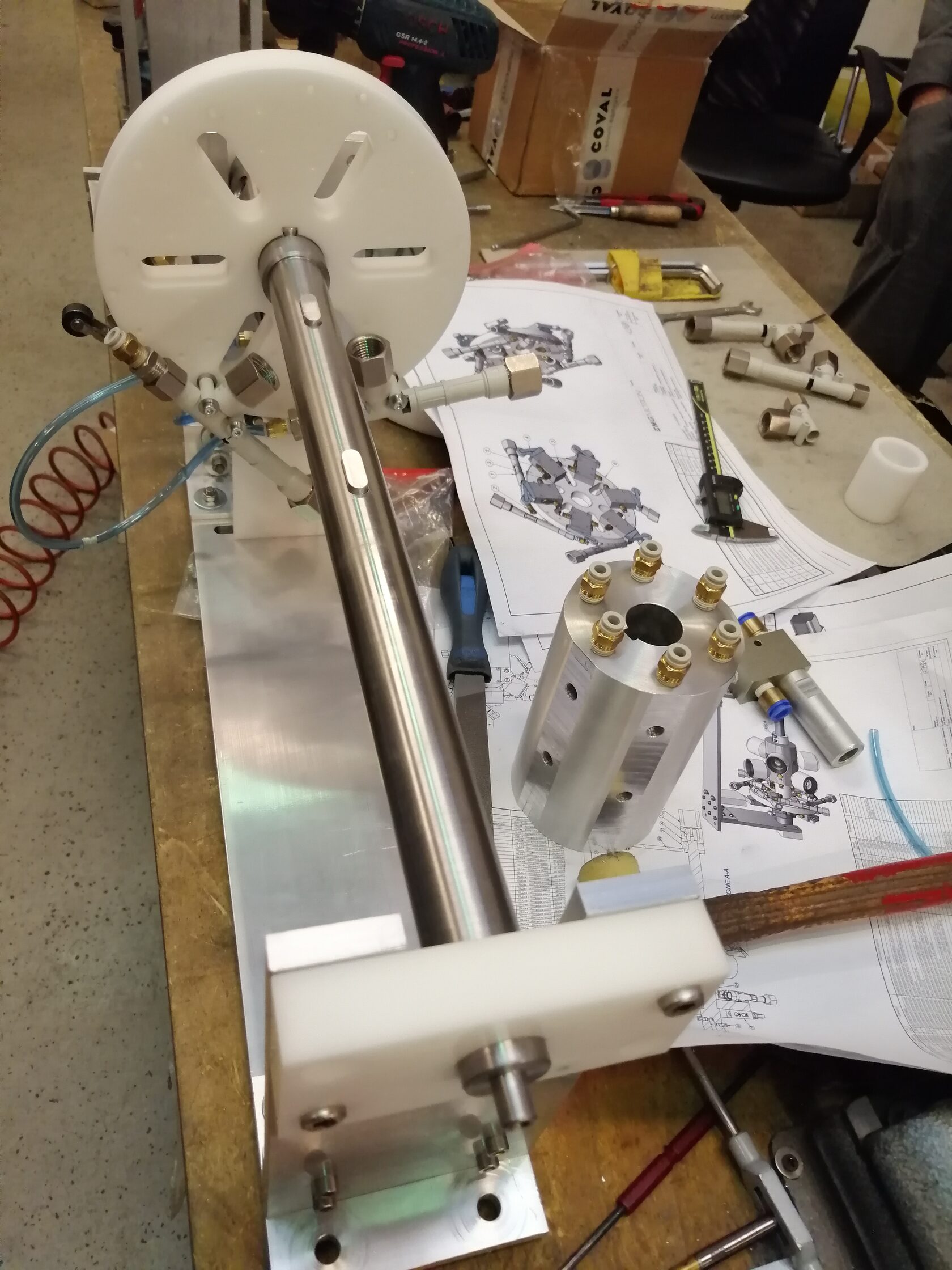

One of the key advantages of working with an experienced CNC manufacturer is the additional engineering support available to guide clients through the entire production process. From initial designs to finished products, our team collaborates closely with clients, offering insights into optimizing tolerances, material choices, and design features that may enhance part performance or cost-efficiency. This level of partnership is rare and can be invaluable for clients who need more than just a supplier—they need a technical ally to help bring their vision to life.

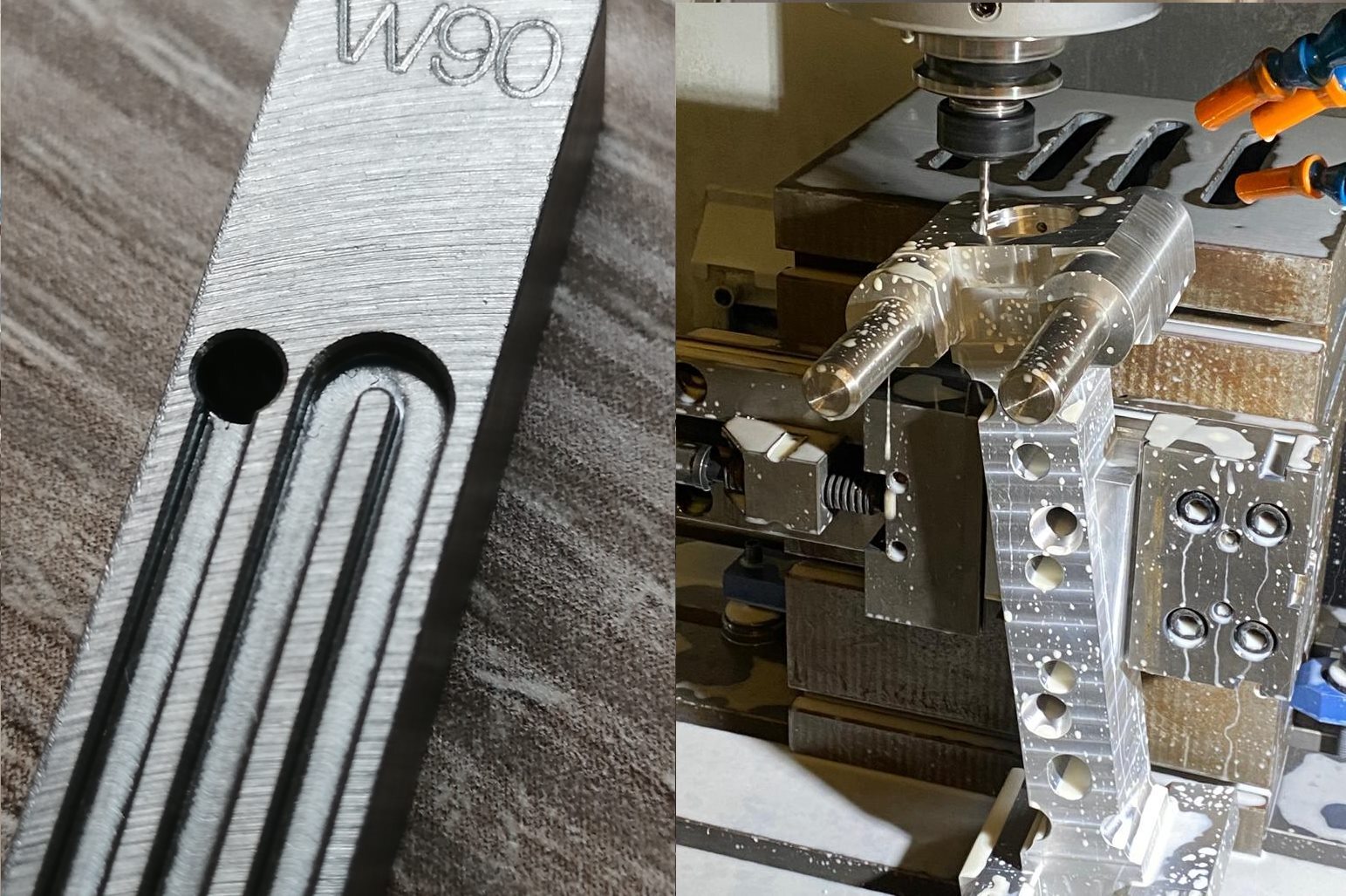

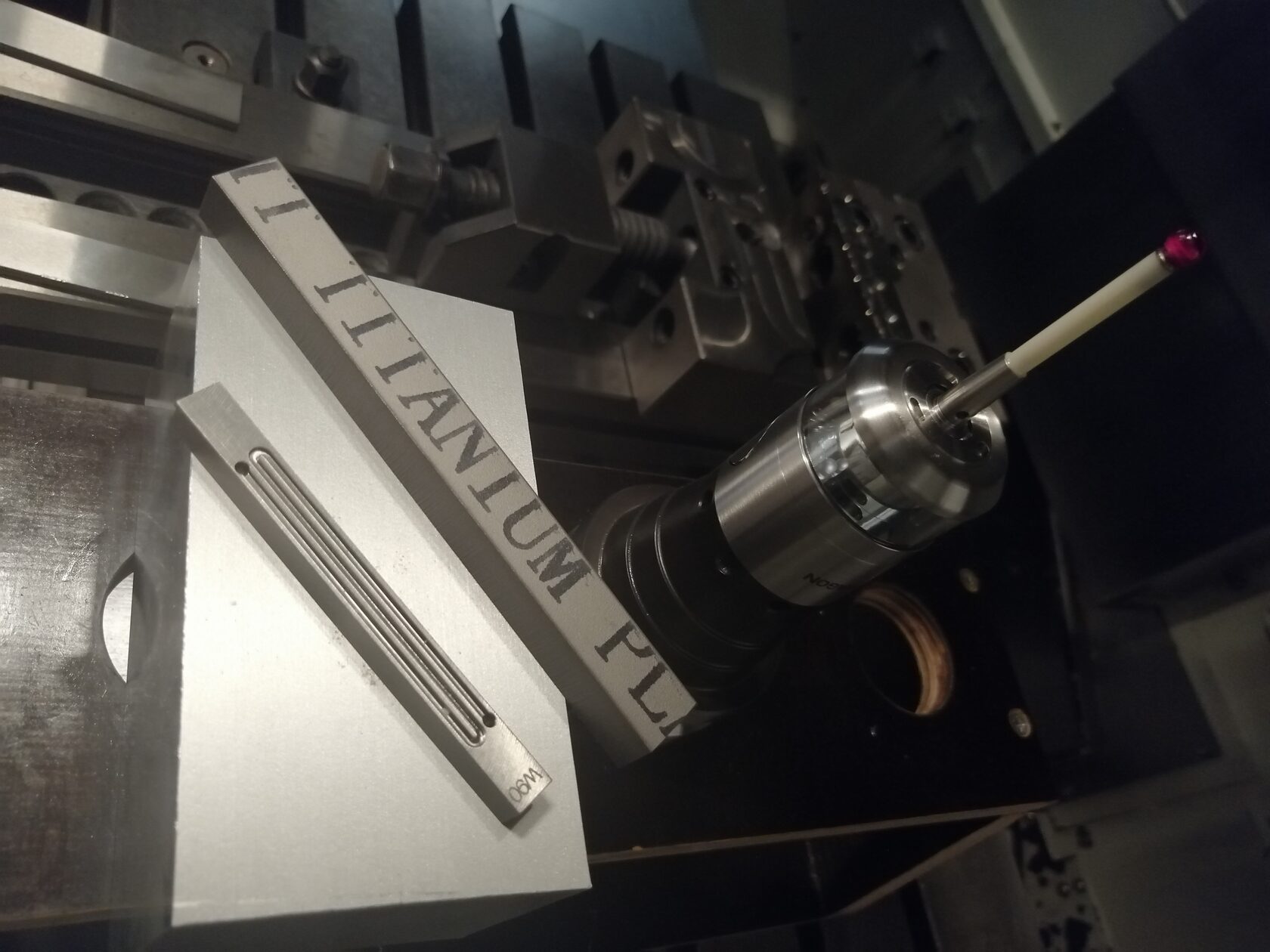

Flexibility and Expertise for Unique Needs

Projects that require unique or limited-run CNC parts are often complex and highly customized. Flexibility, then, is essential. A trusted CNC provider like ours brings a wealth of expertise to meet specific needs, be it in unusual materials, advanced treatments, or intricate designs. With capabilities ranging from precise metal machining to post-production treatments, we offer a full spectrum of services under one roof, reducing lead times and ensuring that each part meets the highest standards of quality and performance.

Competitive Pricing Without Compromising on Quality

For many, competitive pricing is as crucial as quality, especially when dealing with prototypes or specialized components. We understand the cost constraints associated with these projects and have optimized our processes to provide exceptional quality without inflated costs. Our clients benefit from industry-leading CNC manufacturing at competitive prices, proving that high-quality components don’t always come with a premium price tag.

Choosing Reliability for Long-Term Success

In the end, the value of choosing a trusted CNC manufacturer lies not only in the immediate results but also in the long-term relationship built on reliability, expertise, and mutual success. For clients working on high-stakes prototypes or limited production runs, partnering with a dependable CNC provider can make the difference between a project that merely meets specifications and one that exceeds expectations.

When quality, expertise, and flexibility are essential, choosing the right partner matters. At Engmotion, we are proud to support our clients with unmatched engineering capabilities, attention to detail, and a commitment to delivering value in every project, no matter the scale.